Excellent Towing Experience with a Torque Converter Lockup Kit

Necessity is the mother of invention, and, in the case of Marshall Muller, it was necessity that sent him in search of a better solution to the problem of automatic transmission slippage and its associated overheating and excess fuel consumption issues.

Adelaide-based Marshall and his family are avid recreational 4x4 enthusiasts who share a passion for off-grid four-wheeling, caravanning, and camping. But unlike most of us, Marshall is also an electronics and software engineer with 30-plus years of professional expertise in defence, commercial and government R&D projects.

Having travelled and towed extensively throughout Australia in a pair of Mitsubishi Pajeros and a Toyota Landcruiser 200 Series, Marshall knows first-hand each vehicle’s strengths and weaknesses.

“As a driver, you learn to understand your vehicle and how to protect it. We often push our vehicles to their limits, sometimes without realising it, such as when towing in hilly terrain, sand driving or climbing steep off-road tracks,” says Marshall.

“One of the keys to doing this safely and without risking your vehicle is ensuring the right transmission gear is selected for the conditions you are driving in, since that helps maintain momentum, ensure vehicle longevity, and minimises fuel consumption."

“With a conventional automatic transmission, that’s not always possible because vehicle manufacturers tend to optimise the operation of their vehicle transmissions for the average user doing daily driving and touring, rather than towing.

“This leads to the unfortunate situation of having a vehicle that is rated to tow a certain capacity, but which is not particularly happy doing so. The auto transmission may shift up and down the gearbox too frequently, or the gearbox’s lock-up torque converter may not work effectively because the computer-controlled, pre-set conditions for doing so are not being met. This leads to increased fuel consumption, overheating transmission fluid and a range of other problems that we have encountered with our own vehicles.”

Lightbulb moment

It was precisely this scenario that encouraged Marshall to bring his years of professional engineering and 4WD touring experience together to develop his own range of vehicle electronics products.

His MM4X4’s Lockup Kits address the issue of vehicle transmissions calibrated for daily driving and touring use, by electronically changing the characteristics of the auto to make it better suited for towing.

“Some of the big US pick-up trucks have a towing mode designed into them as an available or standard feature for the transmission, but most Australian vehicles don’t yet have this feature,” says Marshall.

The feature he refers to directs the vehicle’s Electronic Control Unit (ECU) to change the transmission's performance to better suit towing. For example, the engine revs out longer before changing gears and delivers better engine braking on declines. To understand how this works it’s necessary to first outline the basics of how an automatic transmission works.

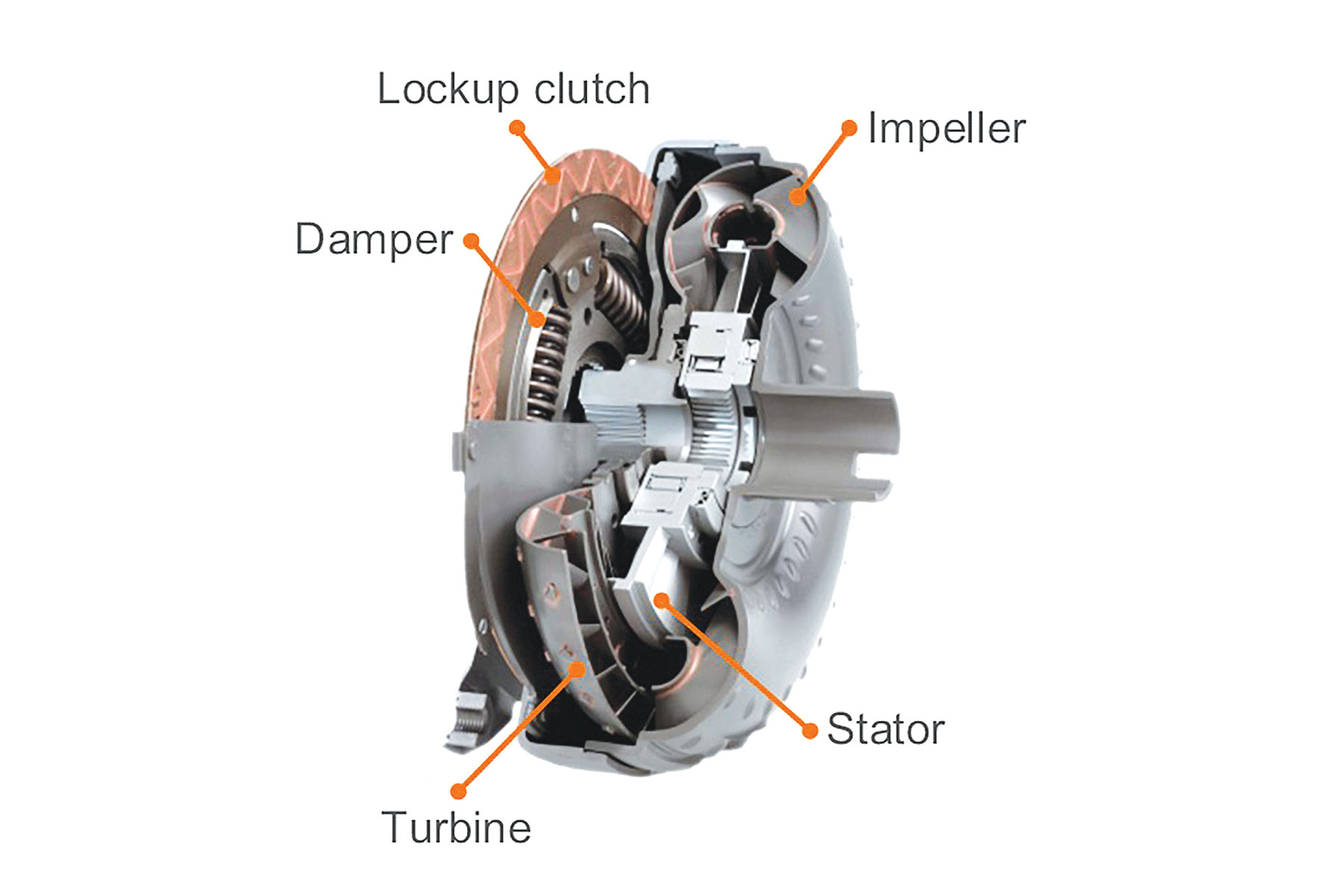

Many readers will have heard the term ‘slush box’ in relation to automatic transmissions. This is because auto transmissions replace the friction clutch of a manual transmission with a fluid coupling, or torque converter, which connects the engine to the transmission via a housing that uses pressurised fluid to transfer power to the gears.

In a manual car, if you want to allow the engine to keep running without moving the car, you disconnect the engine from the transmission by using the clutch. But in an automatic vehicle the torque converter does that job for you allowing the engine to spin independently of the transmission, hence why you can idle in an automatic with just light pressure on the brakes.

When you accelerate in an automatic, the engine speed increases and the fluid circulating in the torque converter drives a high-speed impeller which pushes fluid through a turbine and sends torque to the driven wheels. As the name suggests, a torque converter is designed to multiply the torque of an engine during acceleration, which it does by using turbine vanes on the engine side of the transmission housing to spin the oil in a way that drives another set of vanes on the transmission side of the housing, which in turn drives an output shaft that sends drive to the transmission.

When you accelerate in an automatic, the engine speed increases and the fluid circulating in the torque converter drives a high-speed impeller which pushes fluid through a turbine and sends torque to the driven wheels. As the name suggests, a torque converter is designed to multiply the torque of an engine during acceleration, which it does by using turbine vanes on the engine side of the transmission housing to spin the oil in a way that drives another set of vanes on the transmission side of the housing, which in turn drives an output shaft that sends drive to the transmission.

As the vehicle gathers speeds there is a point where the engine speed increases to almost match the speed of the turbine vanes spinning inside the torque converter. The torque converter has an internal clutch which it then activates to lock the two halves together, eliminating slippage and improving fuel efficiency. This is what’s known as a lock up torque converter.

The lock up advantage

As Marshall explains, because vehicle manufacturers optimise the operation of their vehicle transmissions for daily driving and touring, the lock-up characteristics of the torque converter and gear shift points are not necessarily suited to the more arduous work of towing.

“When towing, a lockup kit offers numerous benefits by changing the operation of the automatic transmission to be ‘closer' to that of a manual gearbox. It does this by activating the lockup clutch of the torque converter in a wider range of driving conditions. When the torque converter clutch is engaged, it performs much like a manual,” says Marshall.

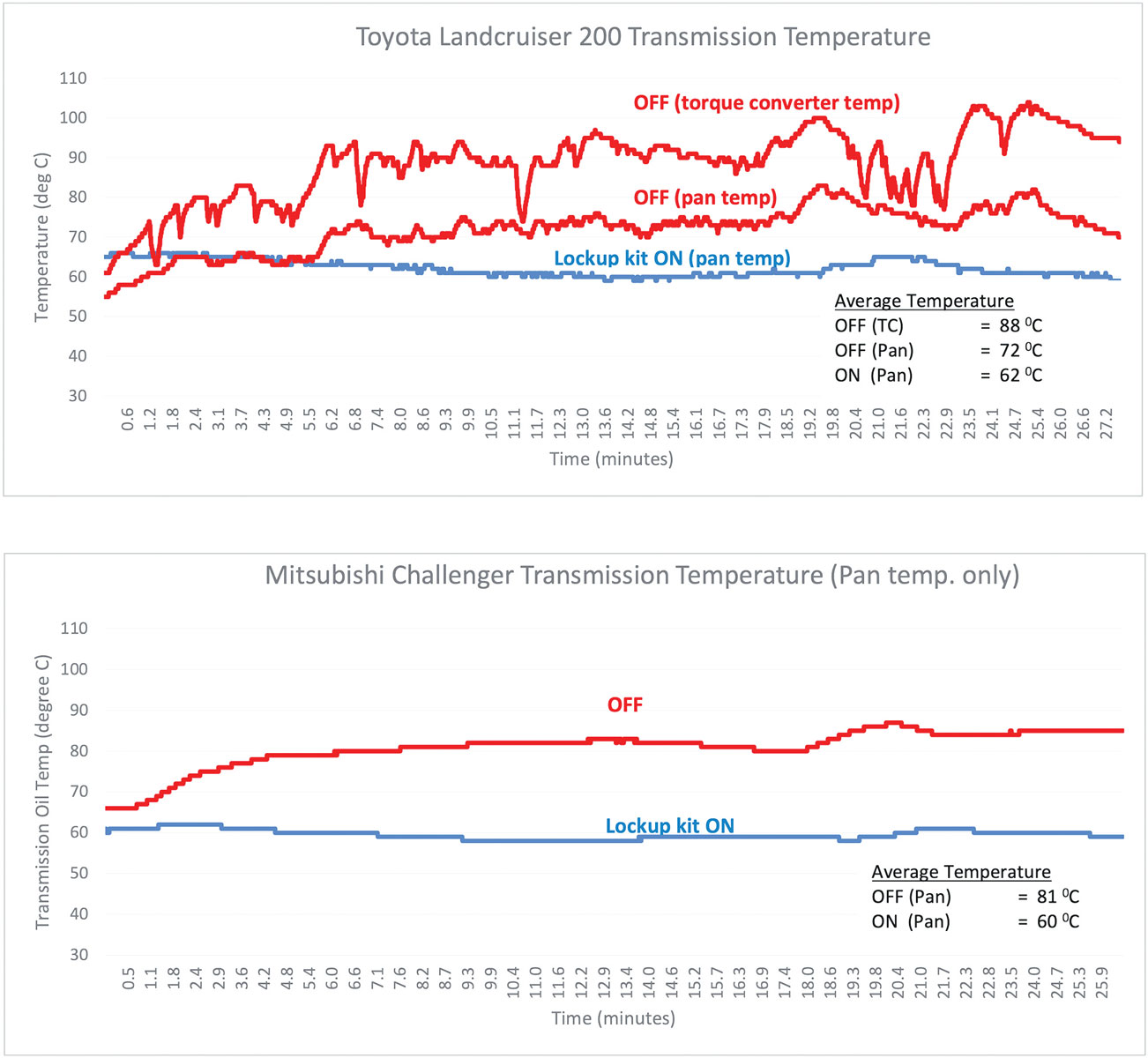

“When working the transmission hard, such as when towing, the torque converter generates a significant amount of heat due to the slippage. This heat is not only potentially damaging to the transmission, but also wastes fuel.”

Among the claimed advantages of MM4x4’s Lockup Kits are lower transmission oil temperatures (which protects the transmission from overheating); superior fuel consumption (because the lockup kit stops the transmission from slipping); better engine braking on hill descents; more direct power to the road, instead of the ‘rubber band’ like feel of an auto and elimination of the transmission LIMP mode problems that can afflict some autos when towing up long inclines.

MM4X4 Lockup Kits have been specifically developed to target vehicles that are used for towing specialising in Toyota and Mitsubishi. The current product range includes kits for the Toyota LC200 and PRADO 150, Mitsubishi Pajero NS, NT, NW and NX, Mitsubishi Challenger PB & PC, and Mitsubishi Triton MQ & MN, although new models are being added all the time.

“Due to the sophisticated behaviour of our kits, each is tailored for a specific make or model. Other kits on the market are generic, and only activate the lockup at a predetermined vehicle speed, which comes with compromises. Our units are far more complex as they digitally communicate with the vehicle ECU so can be specifically tuned for the best performance in each vehicle,” says Marshall.

Fuel savings

One of the key advantages of the system is significant fuel savings. The exact savings are highly dependent on driving conditions, but as a rule of thumb Marshall estimates a 10 per cent saving for most vehicles and has seen as high as 25-30 per cent-plus in Mitsubishi Challenger and Triton models.

“We estimate that a Landcruiser 200 Series towing between two-three tonnes, with the transmission in ‘Drive’ will see an improvement of 10-15 per cent, which equates to between two and three litres per 100km,” he says.

The company website details a comparison test Marshall and his team conducted of an LC200 and a Mitsubishi Challenger over the same route though the Adelaide Hills, which yielded a 14 per cent fuel saving on both vehicles. In testing, MM4X4 saw fuel consumption drop as much as 2L/100 km travelled with the LC200 over a hilly 45km drive. Considering a kit for the 200 is around $700, at today's high cost of fuel ($2.20 per litre) you only need to save about 320 litres before it paid itself off. In practical terms, if you see 20L/100km in towing and dropped to 18 using a lock-up kit, you’ll need to cover about 16,000km before you’re in the black.

But what about my warranty?

A Toyota spokesperson said that Toyota’s warranty coverage does not apply for any damage caused by modifications carried out at a non-Toyota repairer. It will also not cover failures in non-genuine parts and accessories as well as any damage or failures that are caused by such failures.

Similarly, a Mitsubishi spokesperson said installation of non-genuine products could void the manufacturer’s warranty, and that the company urges any owners to weigh this up when considering such modifications.

A third manufacturer we spoke with, who did not want to be named, said the issues go beyond warranty consideration, saying that OEMs (Original Equipment Manufacturers) do thousands of kilometres of product testing and development, and the standard fit torque converters are programmed to lock up when the conditions require it. They are not specific to just towing or just off-roading but designed to suit as many conditions as possible.

In addition, they said, the aftermarket doesn’t have the ability to test to the same standards as OEMs, who also need to adhere to strict emissions standards and achieve targeted NVH tolerance outcomes.

Marshall responds that the situation with regards manufacturer warranty is the same as for any other aftermarket accessory fitted to a vehicle, and that the driver can easily turn the lockup kit on and off, reverting the transmission to normal operation if required.

“People modify their vehicles because the standard package may not meet their needs. Modifications such as a bull bar, underbody protection, lifted suspension, snorkel, and stronger tyres will improve vehicle protection when off-road,” he says.

“Similarly, a lockup kit improves performance when towing for better fuel economy and lower transmission temperatures. Overheating is the main cause of expensive transmission rebuilds.

“Because we design and manufacture our products, we fully support them. We provide repairs, upgrades, and free firmware updates for minor improvements and features, with the only cost to the customer being return postage and handling.”

MM4X4 Lockup Kits

MM4X4 Lockup Kits are fully automatic making them virtually ‘foolproof’ according to Marshall. They work through digital communication with the vehicle Electronic Control Unit (ECU) to obtain information on revs, speed, gear, engine load and more. The 'black box' style units come neatly packed with everything needed for home fitment, including the wiring harness that goes to the ECU, the palm-sized control unit with internal computer and relays, an LED switch to engage the lockup kit and show its status, and OBD2 cable.

In the case of a LandCruiser 200 Series, the kit is typically located up alongside the driver’s side footrest or ‘dead pedal’, with the resistor attached by self-drilling screws to the existing metal of the console with the wiring run through and underneath the internal trim to the passenger side, before being passed through an existing rubber grommet to the engine bay and ECU.

Depending on product version, the kits cost between $495 and $895 RRP and come with a detailed, colour installation booklet with step-by-step photos, aimed at DIY install. Marshall estimates the kits take between 1.5 to 2.5 hours to install, depending on product and vehicle model, while a professional installation will set you back between $165 and $350, dependant on labour rates varying between $110-$140/hour.